Those in the packaging industry depend on precision and efficiency to reach their production goals. It’s up to you to ensure that your converting technology is up to the challenge.

To learn how the Maxcess line of products and custom solutions can expedite and improve your packaging applications, contact a Maxcess representative today.

Your One-Stop-Shop for Custom Packaging Solutions

Maxcess offers a variety of state-of-the-art products designed to simplify and accelerate your packaging manufacturing processes. Packaging manufacturers around the world trust in our technology and custom end-to-end solutions to keep their businesses running smoothly and efficiently at all times. The right technology, combined with the right packaging applications, can minimize costs, reduce waste, and maximize for your customers.

Below you’ll find a sampling of the packaging fields to which our products and services cater. If you have questions, or would like to know how the custom solutions provided by Maxcess can benefit your packaging operations, contact one of our representatives today.

Flexible Packaging

Flexible packaging—blown film, coating, laminating—keeps the products we love safe, convenient, and attractive for consumers. But producing the right flexible packaging efficiently and at a fair price point can be challenging. In addition to custom packaging solutions, Maxcess offers sturdy and precise products including precision rolls, slitters, and web guiding systems designed to accurately convert the most delicate of materials all the way to the most rigid.

Featured Products

VisionMax 100% Inspection Systems

Catch defects in real-time before they become critical and costly with our state-of-the-art and easy-to-use 100% vision inspection systems.

VisionConnect Automation

Harness your data to run smarter. Configure VisionConnect to generate roll maps, insert tags, print codes to serialize product, review rolls for quality, control slitter and doctor machines, or automatically remove waste at the final converting process.

DSE-45 Wideband Ultrasonic Sensor

A high-precision wide band ultrasonic sensor that delivers reliable and accurate measurements in a variety of industrial applications.

AccuStar® UltraFilm™ Flexible Die (Film Applications)

The AccuStar™ UltraFilm™ is considered the “all-star” of RotoMetrics’ flexible die solutions featuring the exacting precision tolerances required to convert the most challenging films and liners in today’s market.

RD300 Solid Die

Cut precision parts, thick substrates and thin films or synthetic constructions with ease. The RD300 solid die provides a totally precise performance whether in complex long run to-liner, challenging zero clearance, or complicated metal-to-metal converting projects.

Control Series Electronic Knifeholders

Maximize operator safety, productivity and roll quality with Tidland’s Control Series. Features include an LED-backlit touchscreen interface, enhanced durability and available wireless operation.

Edge-Trim

With Tidland’s Edge-Trim, reduce waste and increase productivity. This self-contained shear slitting unit continuously moves flexible webs and virtually eliminates blade setup time during trim changes without disturbing slit geometry for high trim quality.

TS Load Cells

TS load cells provide the most consistent tension control regardless of temperature changes. They’re rugged and highly accurate, measuring tension in any unwind, rewind or intermediate web processing application.

Webex Idler Rolls

We offer more than 400 standard configurations and numerous customizable options available for coating, plating, finish, groove patterns, shaft style, and environmental capabilities.

Valley Roller Rubber Covered Roll Solutions

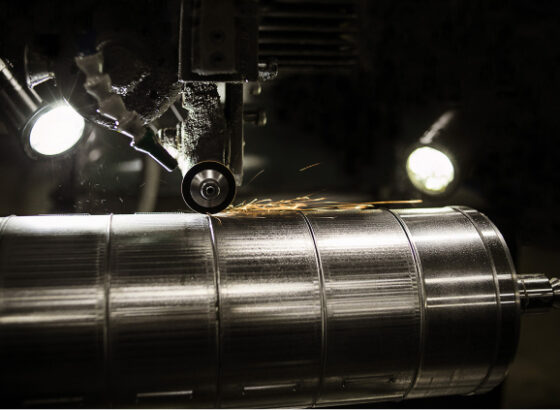

With more than 3,000 custom rubber compounds, you will dramatically improve your performance through our precise grinding tolerances that exceed industry standards, including the option for inspection for highly accurate measurements in applications requiring a near-perfect grind profile.

Food and Beverage

Believe it or not, the right food and beverage packaging is just as important as the product itself. And converting food packaging materials of all kinds—rigid and non-rigid—is a field in which Maxcess brands shine. We offer the tools and resources necessary to generate a wide range of food and beverage label and packaging applications accurately and efficiently.

Featured Products

VisionMax 100% Inspection Systems

Catch defects in real-time before they become critical and costly with our state-of-the-art and easy-to-use 100% vision inspection systems.

VisionConnect Automation

Harness your data to run smarter. Configure VisionConnect to generate roll maps, insert tags, print codes to serialize product, review rolls for quality, control slitter and doctor machines, or automatically remove waste at the final converting process.

Cygnus Tension Controller

The Cygnus Tension Controller is an advanced, intuitive tension controller in a compact enclosure that's easy to navigate for operators.

D-MAX Enhanced Web Guiding Controller

A compact and easy-to-use web guide controller that offers precise and reliable control for a variety of industrial applications.

AccuPrime™ Flexible Die (Standard Paper & Film Applications)

The AccuPrime™ Flexible Die is the most versatile cutting die in the RotoMetrics portfolio, engineered to convert a wide range of paper and synthetic materials, including film, paper, laminated papers, tag material and paperboard.

RotoRepel™ Adhesive Control Treatment

RotoRepel™ offers comprehensive adhesive control benefits far beyond nonstick properties, improving overall die and press performance in several ways for more longevity and better efficiency.

Performance Series Knifeholder

Achieve faster setups, increased productivity and unrivaled finished roll quality with the Performance Series Knifeholder. Available in three sizes to accommodate a wide range of slitting materials and web speeds in a wide range of applications.

Edge-Trim

With Tidland’s Edge-Trim, reduce waste and increase productivity. This self-contained shear slitting unit continuously moves flexible webs and virtually eliminates blade setup time during trim changes without disturbing slit geometry for high trim quality.

Webex Idler Rolls

We offer more than 400 standard configurations and numerous customizable options available for coating, plating, finish, groove patterns, shaft style, and environmental capabilities.

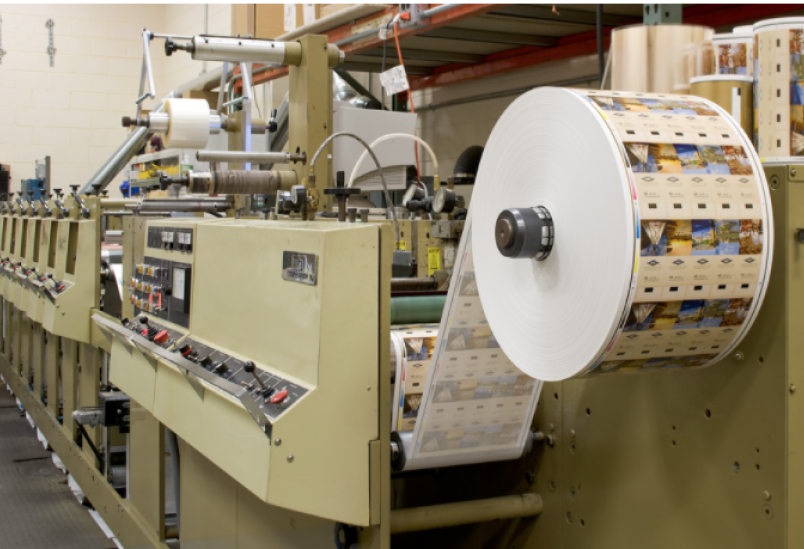

Tag and Label

The look of your product’s tag or label can most certainly sway an indecisive customer to, or away from making a purchase. With a variety of flexible and solid die cutting tools and accessories, Rotometrics, a Maxcess brand, is a favorite for those in the tag and label sector of the packaging industry. Built to last, our dies deliver precise execution time and time again. Ask how our other Maxcess brands can further improve your tag and label press performance.

Featured Products

AccuStar® UltraFilm™ Flexible Die (Film Applications)

The AccuStar™ UltraFilm™ is considered the “all-star” of RotoMetrics’ flexible die solutions featuring the exacting precision tolerances required to convert the most challenging films and liners in today’s market.

Magnetic Cylinders

The AccuBase™ Magnetic Cylinders are precision-engineered with exacting tolerances and enhanced dimensional stability to optimize flexible die accuracy. Magnetic cylinders are available for a full range of label presses and converting machinery.

RD300 Solid Die

Cut precision parts, thick substrates and thin films or synthetic constructions with ease. The RD300 solid die provides a totally precise performance whether in complex long run to-liner, challenging zero clearance, or complicated metal-to-metal converting projects.

RotoRepel™ Adhesive Control Treatment

RotoRepel™ offers comprehensive adhesive control benefits far beyond nonstick properties, improving overall die and press performance in several ways for more longevity and better efficiency.

FIFE-500 Web Guiding System

Leverage the latest in web guiding technology and improve efficiency with the cost-effective FIFE-500, ideal for narrow web and nonwoven applications.

TS Load Cells

TS load cells provide the most consistent tension control regardless of temperature changes. They’re rugged and highly accurate, measuring tension in any unwind, rewind or intermediate web processing application.

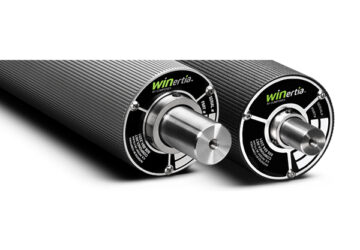

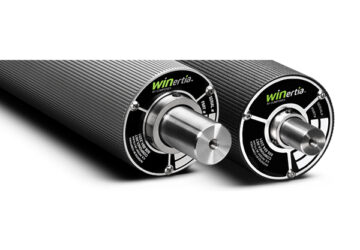

WINertia™ AV-Air Vent Aluminum Dead Shaft Idler

Featuring a special air vent design for consistent, reliable performance in demanding environments.

RFID

Believe it or not, the right food and beverage packaging is just as important as the product itself. And converting food packaging materials of all kinds—rigid and non-rigid—is a field in which Maxcess brands shine. We offer the tools and resources necessary to generate a wide range of food and beverage label and packaging applications accurately and efficiently.

Featured Products

D-MAX Enhanced Web Guiding Controller

A compact and easy-to-use web guide controller that offers precise and reliable control for a variety of industrial applications.

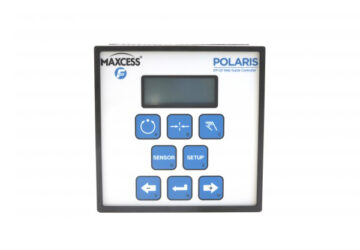

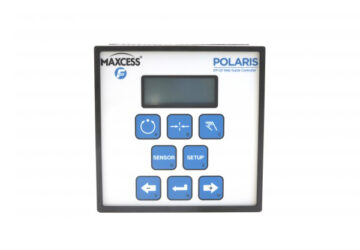

Polaris DP-20 Web Guide Controller

A high-performance web guide controller that provides precise and reliable control for a variety of industrial applications.

AccuPrime™ Flexible Die (Standard Paper & Film Applications)

The AccuPrime™ Flexible Die is the most versatile cutting die in the RotoMetrics portfolio, engineered to convert a wide range of paper and synthetic materials, including film, paper, laminated papers, tag material and paperboard.

DuraLine Special Flexible Die (Challenging Film Applications)

Get the sharpness and superior cutting ability of our thin film application dies combined with the reliability and longevity associated with our proprietary life extending coating processes with DuraLine Special.

Magnetic Cylinders

The AccuBase™ Magnetic Cylinders are precision-engineered with exacting tolerances and enhanced dimensional stability to optimize flexible die accuracy. Magnetic cylinders are available for a full range of label presses and converting machinery.

Anvils

Unlock the power of precision with our anvil solutions by RotoMetrics. Choose from a range of solutions, including Base Anvils, Adjustable Clearance Anvils and AccuAdjust, RotoAdjust Dual Adjustable Anvils.

CL Cantilevered Load Cells

The CL Cantilevered Load Cells by MAGPOWR are the most cost-effective on the market, with the unique ability to accept virtually any roll and shaft assembly.

Webex Heat Transfer Rolls (Chill Rolls)

A uniquely engineered internal temperature management system allows for precise temperature control, ensuring consistent, reliable performance in heat transfer applications.

Corrugated

Corrugated packaging is a sustainable, durable, and cost-effective solution for your company’s packaging needs. But you need the right converting solutions to make it feasible and worth your while. Fortunately, the Maxcess brands offer the technology and expertise to get you on the right track. Our line of flexible and solid dies, for instance, are the perfect solution for converting cartons, blister boards, paperboard containers, and any other cardboard packaging application you can fathom. Designed to reduce your operational costs, our dies work seamlessly and efficiently, making each cut just as precise as the next.

Featured Products

VisionMax 100% Inspection Systems

Catch defects in real-time before they become critical and costly with our state-of-the-art and easy-to-use 100% vision inspection systems.

VisionConnect Automation

Harness your data to run smarter. Configure VisionConnect to generate roll maps, insert tags, print codes to serialize product, review rolls for quality, control slitter and doctor machines, or automatically remove waste at the final converting process.

D-MAX Enhanced Web Guiding Controller

A compact and easy-to-use web guide controller that offers precise and reliable control for a variety of industrial applications.

RD250 Solid Die

As a superior solid die, the RD250 is ideal for to-liner and metal-to-metal applications. Enhanced with dedicated steel and machine finishing for precise blade profiles and tighter tolerances ensure it will produce cost-effective results and resolve converting challenges.

Boschert Safety Chucks

Tidland Boschert Safety Chucks are pre-engineered for roll support and torque transfer in unwind and rewind applications, available in a variety of options depending on the level of safety and automation required.

Crushed Core Restorers

Designed to reopen crushed cores, the Tidland Roll Savers can save you thousands of dollars by allowing shaft insertion on rolls that would otherwise be considered scrap material.

Webex Heat Transfer Rolls (Chill Rolls)

A uniquely engineered internal temperature management system allows for precise temperature control, ensuring consistent, reliable performance in heat transfer applications.

Pharmaceutical

Pharmaceutical packaging must be sturdy, functional, and keep the product safe from light, moisture, and outside elements. And, like every aspect of the industry, there is no margin for error. It is essential that manufacturers use the proper tools and resources at hand to package their pharmaceutical products properly and safely. The Maxcess team has the technology, knowledge, and ingenuity necessary to optimize your manufacturing processes and produce the pharmaceutical packaging your products and customers deserve.

Featured Products

VisionMax 100% Inspection Systems

Catch defects in real-time before they become critical and costly with our state-of-the-art and easy-to-use 100% vision inspection systems.

VisionConnect Automation

Harness your data to run smarter. Configure VisionConnect to generate roll maps, insert tags, print codes to serialize product, review rolls for quality, control slitter and doctor machines, or automatically remove waste at the final converting process.

Cygnus Tension Controller

The Cygnus Tension Controller is an advanced, intuitive tension controller in a compact enclosure that's easy to navigate for operators.

D-MAX Enhanced Web Guiding Controller

A compact and easy-to-use web guide controller that offers precise and reliable control for a variety of industrial applications.

RD300 Solid Die

Cut precision parts, thick substrates and thin films or synthetic constructions with ease. The RD300 solid die provides a totally precise performance whether in complex long run to-liner, challenging zero clearance, or complicated metal-to-metal converting projects.

Edge-Trim

With Tidland’s Edge-Trim, reduce waste and increase productivity. This self-contained shear slitting unit continuously moves flexible webs and virtually eliminates blade setup time during trim changes without disturbing slit geometry for high trim quality.

Foot Mounted Magnetic Particle Brakes

Transform your reliable, durable, foot-mounted MAGPOWR C Series Clutches into brakes with a locking bracket.

Foot Mounted Magnetic Particle Clutches

The cost-effective MAGPOWR C Series Magnetic Particle Clutch is reliable and durable, providing silent operation that’s ideal for cycling and overload applications.

Wound Care

Like all products in the healthcare and pharmaceutical industries, wound care products must be engineered to meet strict specifications. To ensure that your wound care manufacturing processes are yielding top notch results quickly and efficiently, while minimizing downtime and waste, you need the right tools and the right solutions in place. Rotometrics line of flexible and solid dies, for example, are equipped to handle large quantities of wound care substrates of all types. Let our Maxcess team of web handling experts help you keep your wound care manufacturing operations cost effective and reliable.

Featured Products

VisionMax 100% Inspection Systems

Catch defects in real-time before they become critical and costly with our state-of-the-art and easy-to-use 100% vision inspection systems.

VisionConnect Automation

Harness your data to run smarter. Configure VisionConnect to generate roll maps, insert tags, print codes to serialize product, review rolls for quality, control slitter and doctor machines, or automatically remove waste at the final converting process.

RD300 Solid Die

Cut precision parts, thick substrates and thin films or synthetic constructions with ease. The RD300 solid die provides a totally precise performance whether in complex long run to-liner, challenging zero clearance, or complicated metal-to-metal converting projects.

DSE-17 Digital Wideband Infrared Sensor

Most suitable for applications where opacity or density variations may occur, it can track up to 4 independent web edges simultaneously. The DSE-17 sensor eliminates the need for manual repositioning of the sensor, removing moving parts and reducing maintenance and downtime.

Edge-Trim

With Tidland’s Edge-Trim, reduce waste and increase productivity. This self-contained shear slitting unit continuously moves flexible webs and virtually eliminates blade setup time during trim changes without disturbing slit geometry for high trim quality.

Boschert Safety Chucks

Tidland Boschert Safety Chucks are pre-engineered for roll support and torque transfer in unwind and rewind applications, available in a variety of options depending on the level of safety and automation required.

TS Load Cells

TS load cells provide the most consistent tension control regardless of temperature changes. They’re rugged and highly accurate, measuring tension in any unwind, rewind or intermediate web processing application.

Webex Heat Transfer Rolls (Chill Rolls)

A uniquely engineered internal temperature management system allows for precise temperature control, ensuring consistent, reliable performance in heat transfer applications.

Wipes

For wipes manufacturers, your customers only require that your product be dependable time and time again. Products such as baby wipes, disinfectant wipes, makeup remover wipes, and Wet Wipes are designed for convenience above all else. And if you aren’t using the right tools to ensure convenience for your customer, they’re going to find someone who does. By no means are our line of rotary dies are not a “one-size-fits-all” solution. We will work with your team to get you the equipment ideal for your individual applications. Let us help you keep your processes optimal, your costs low, and your customers happy.

Featured Products

VisionMax 100% Inspection Systems

Catch defects in real-time before they become critical and costly with our state-of-the-art and easy-to-use 100% vision inspection systems.

VisionConnect Automation

Harness your data to run smarter. Configure VisionConnect to generate roll maps, insert tags, print codes to serialize product, review rolls for quality, control slitter and doctor machines, or automatically remove waste at the final converting process.

DSE-22

A high-precision infrared sensor that delivers reliable and accurate measurements in a variety of industrial applications.

RD300 Solid Die

Cut precision parts, thick substrates and thin films or synthetic constructions with ease. The RD300 solid die provides a totally precise performance whether in complex long run to-liner, challenging zero clearance, or complicated metal-to-metal converting projects.

Performance Series Knifeholder

Achieve faster setups, increased productivity and unrivaled finished roll quality with the Performance Series Knifeholder. Available in three sizes to accommodate a wide range of slitting materials and web speeds in a wide range of applications.

GX Ultra Lightweight Air Shaft

Made with lightweight, high-strength aluminum and innovatie 2-piece expanding element, the Ultra-Light GX Air Shaft delivers unmatched performance in many unwind and rewind applications.

Leaf Shafts

Ideal for the elimination of thin wall core deformation, leaf shafts are designed for a wide range of converting applications and delicate materials in particular.

Boschert Safety Chucks

Tidland Boschert Safety Chucks are pre-engineered for roll support and torque transfer in unwind and rewind applications, available in a variety of options depending on the level of safety and automation required.

CL Cantilevered Load Cells

The CL Cantilevered Load Cells by MAGPOWR are the most cost-effective on the market, with the unique ability to accept virtually any roll and shaft assembly.

Webex Idler Rolls

We offer more than 400 standard configurations and numerous customizable options available for coating, plating, finish, groove patterns, shaft style, and environmental capabilities.