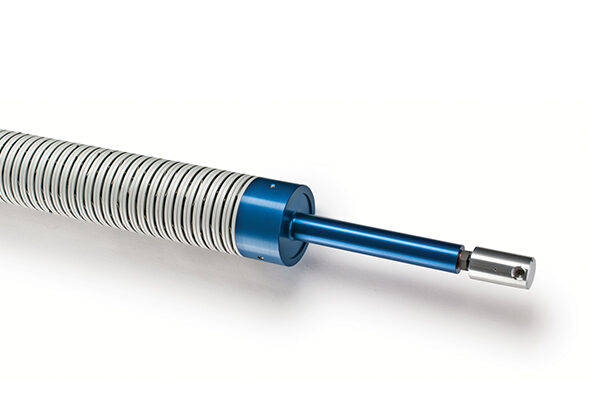

D490 Differential Shaft

Eliminates dust in the roll wind process with internal slip control

Ensures best quality wound rolls with multiple-point contact on the core ID

Consistent, predictable tension control on a variety of materials with pneumatic friction torque against a machined cartridge

D490 Differential Shaft Overview

The D490 Differential Shaft holds rolls straight and true. Interchangeable cartridges allow you to determine how the shaft engages the core in order to best suit the material and core you’re running. Choose from a heavy gauge wire spring design (D490S) for fiber cores, or a 2-row, 12-ball, torque activated design (D490B) for fiber or PVC cores.

The result is improved finished roll quality, reduced scrap and fast, easy setups for even the most sensitive materials. Because D490 Differential Shafts are manufactured in North America, Europe and China, they are easily sourced and supported worldwide. All components conform to Tidland’s high quality standards and are interchangeable regardless of where the shaft is installed.

*Call Tidland Customer Service to discuss options for your specific application

D490 Differential Shaft

| Core ID Range | 3.00 in, 3.005 - 3.040 in76.2 mm, 76.327 - 77.216 mm |

|---|

D490 Differential Shaft - Spring Cartridge D490S

| Core Material | Fiber onlyFiber only |

|---|---|

| Minimum Slit Width* | 14 mm14 mm |

| Standard Ø | 3.00 in76.2 mm |

| Cartridge Width | 6, 10, 20 mm6, 10, 20 mm |

| Tension Range | 0.25 - 2 pli43.8 - 350.3 Nm |

D490 Differential Shaft - Ball Cartridge D490B

| Core Material | Fiber, PVCFiber, PVC |

|---|---|

| Minimum Slit Width* | 0.79 in20 mm |

| Standard Ø | 3.00 in76.2 mm |

| Cartridge Width | 9, 24 mm9, 24 mm |

| Tension Range | 0.50 - 4 pli 87.6 - 700.5 Nm87.6 - 700.5 Nm |

User Manuals

Product Sheets

Request for Quote (RFQ)

- Battery

- Cardboard

- Flexible Packaging

- Food and Beverage

- Nonwovens

- Packaging

- Pharmaceutical

- Specialty Converting

- Tag and Label

- Towel and Tissue

Related Products

D-MAX OI-TS Operator Interface

User-friendly touchscreen operator interface allowing for easy and intuitive control of web guiding systems in industrial applications.

Control Series Electronic Knifeholders

Maximize operator safety, productivity and roll quality with Tidland’s Control Series. Features include an LED-backlit touchscreen interface, enhanced durability and available wireless operation.

DTR-65 Digital Tension Readout

The DTR-65 offers the ability to have a tension display on a machine panel with the option to also output a tension reference to a drive or PLC to remotely display or control tension.

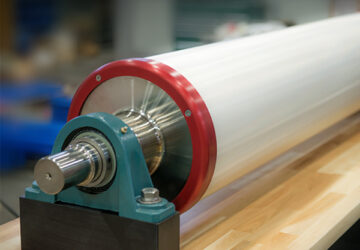

Vacuum Tension Rolls

A uniquely engineered internal vacuum system provides a strong, stable grip on a variety of materials, ensuring consistent and reliable web handling.